To have a distinctive model for my Gundam Unicorn collection.

Duration: est 2-3 months (very little time to work on this model due to tight schedule)

Note: Ordered this from E2046. And I must say, the packaging is really good. They make effort to ensure the items will not be broken due to posting and handling. Even the V-Fins are taped to a hard backing. Good stuff.

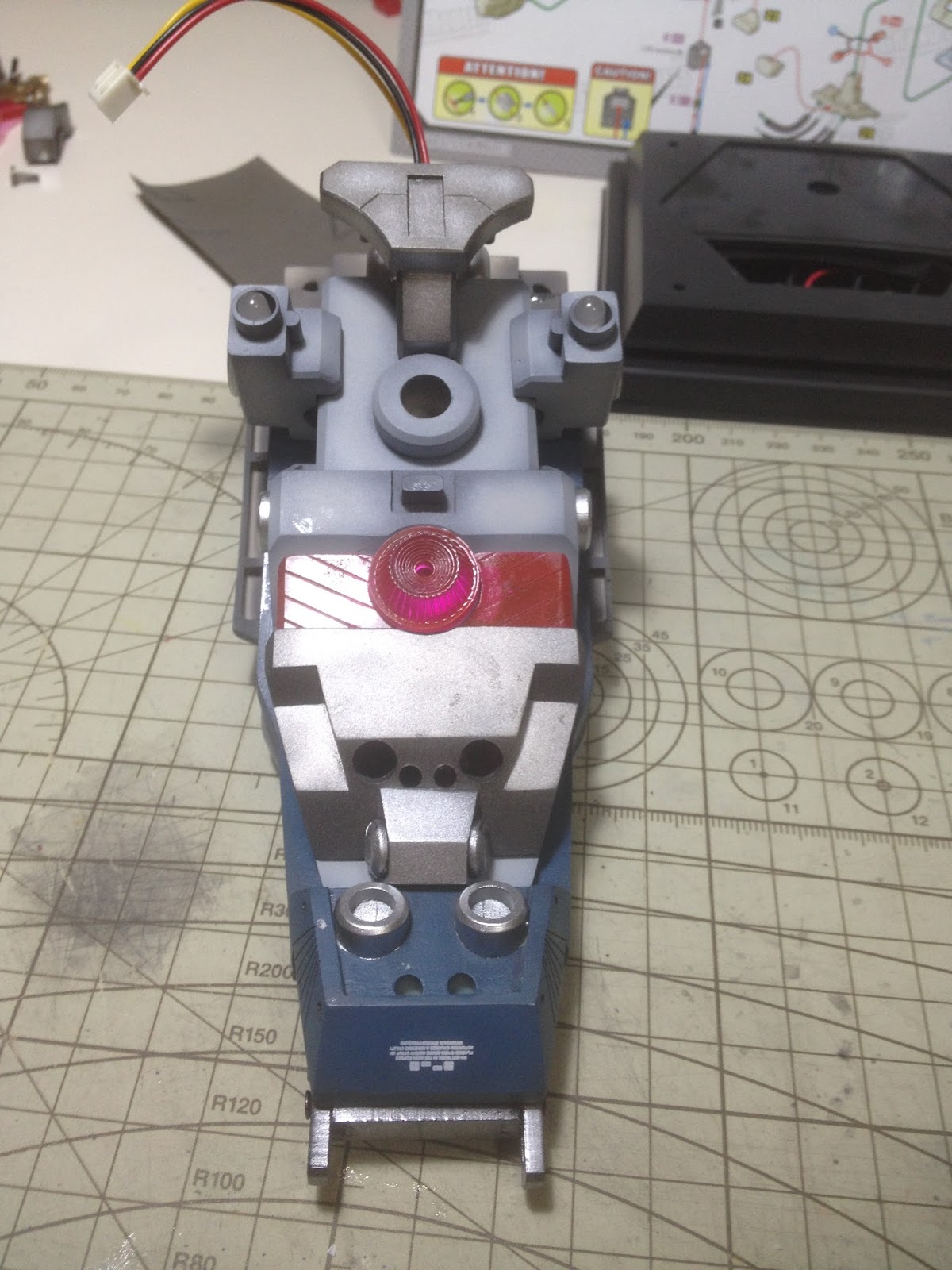

Its contents...

Note that the waterslide decals are precut! And very little excess is exposed when it is applied on the target surface. Wish Bandai had done this with all their Gundam kits...

[update] The instruction sheet shown above is... Efficient. Read it VERY closely before assembly and wiring. It's so "efficient" that you MUST read it several times even when you thought you understood it... I guess you know what I'm trying to elaborate here. Come on GSM, you can do better instruction sheet than this to compliment such a well molded piece.

The Build

This being the 3rd resin kit I have done, I have to acknowledge that this is really well molded. Not only there are very few flaws on the parts, the parts that needs to be joint together, fits perfectly well without major putty nor cutting.

[Update: The rear part of the head had a very tight fitting that refuses to fit into the metal frame. A lot of sanding and cutting was made to make sure it fits. Probably its a defect or it was intentional... No idea...]

As with all resin cast, removing the excess nurbs are always a risky affair for me. Cut too much I might create a crater. Cut too little I will need to file alot and resin is bad for health... Tried sawing but it creates too much dust too... So I tried using my new scribing tool (which I bought it to scribe my PG Zeta Gundam).

Here's how:

|

| Draw a visible line to scribe |

|

| Start scribing a very deep line. No dust but long strands of visible resin which is easy to clean up |

|

| Notice how deep the line is? Well, just make sure its about to break off. |

|

| This is a risky part. If scribing not deep enough, it will create a crater. Be careful. |

|

| A clean snap off! |

|

A simple #400 - #600 wet sanding will clean this off in no time!

|

Note: All resin kits have to be wet sand due to what I read on how it can affect the lungs.

Once all the parts are sand, the parts will be built together using tapes to ensure all parts fits nicely. Then all these parts will be painted using resin surfacer.

With the surfacer done, more flaws can be seen. There are no major ones for this kit. Just use normal putty will do the trick.

Moving on to painting...

The Painting

For this project, I have decided not to have a black base. Instead,

60% Surfacer (neutral grey) & 40% Black = German grey lookalike.

For most of the parts, I reused the remaining paints from the PG Zeta.

The results were fantastic.

Hey! I am really getting the hang of shading! The entire paint job took me only 4-5hrs.

As most of my available time has been booked by my son's activities (playing Black Ops 2), I got only night time to spray the clear coat and it was a risk which I'm prepared to take. But the results looked great! This confirmed that the new Mr. Dry Booth is working well?! No fogging! Clear as it should be! So to me, its working good enough!

[Note]

However, after 4 - 5 hours of airbrushing, I did noticed that my Mr. Linear Compressor had quite a lot of water trapped in the regulator. Not sure if this is usual. Okay, I'm off topic... Will write a review on these new gadgets soon.

The Wiring

To me, this is the toughest part in the entire kit. I have been very lousy at soldering since my school days... Either having cold joints or melting the wire's jacket or creating loads of messy ugly solder joint...

Hopefully I can pull this off...